How to make your own replacement axles

The easy way to replace your axles and wheels is by finding a source car that has the same axle/wheels size as the one you're building, but sometimes that doesn't always happen. And sometimes you just want the wheels off one to put on another, simply for aesthetics. Either way, the hunt for axles can be challenging. Thankfully, you can create your own axles that are just the right size with a few extra accessories.

Overview

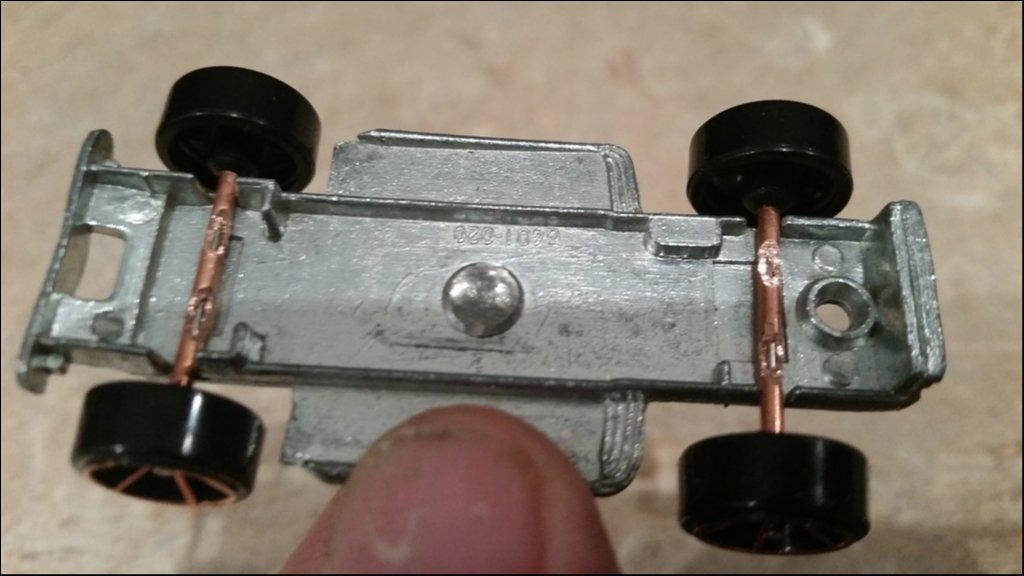

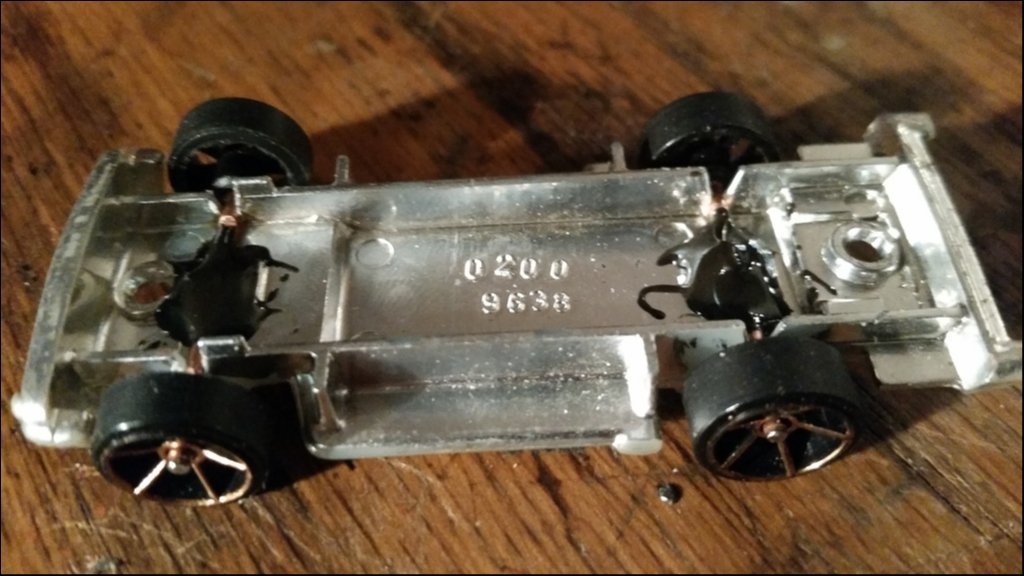

You'll be using hobby tubing as a sheath for existing Hot Wheels axles to create a new complete axle. These custom axle replacements can be made to fit whatever size you need.

What you need

- 1/16" metal tubing. Available in packs at stores like Hobby Lobby.

- Dremel or hobby grinding tool

- Wire cutters or whatever you use to snip axles in half

- JB Kwik or JB Weld

- Clay or putty for temporarily holding things together

We're also assuming you have the original axles you want to use. For the sake of this article, let's assume you have an FTE axle that you want to use in a new build.

Making your own replacement axles

Step 1: Cut your original axle in half. Use cutters or a Dremel if you like. You should also find the wheels you want to use, original or otherwise.

Step 2: Cut/grind to remove the tabs on the chassis you're using. It doesn't take much. You don't want to change the channel where the original axle was sitting.

Step 3: Take the hobby tubing and measure it against the width of the chassis. You want the tubing to be pretty flush with the chassis. Mark the tubing and use your Dremel to cut it at that point. This will be the sheath for your axles.

Step 4: Place your fresh cut axle tube into axle channel on the chassis. Grind, cut, and sand things until you're happy with its size and how it fits. At this point, you can use some clay or putty to hold the tube in place, or use the JB Kwik to make it more permanent...it's up to you and depends how you handle the next step.

Step 5: We need to create two little "windows" in the tube so that you can see the axle inside the tube. Take a Sharpie and mark two points on the tube where the axle will be when inside the tube. Use your Dremel to grind a hole in the tube where those marks are.

Now insert the two axle halves into each end of your axle tube. You should see the axle in the little window hole you grinded out. Pay attention to the amount of "play" that exists between the wheels and the tube sheath. Just like a real car, you don't want too much wobble with your wheels or it can slow you down.

Once you're happy with alignment, add some JB Kwik into the tube window, covering the axle inside. Before it all sets, put the car into an alignment jig or whatever you use to keep things straight. Let the everything dry and you should have a new axle ready to roll.

With some patience and a little luck, you'll have a custom made axle and wheel combo that will be a winner. It's a fickle process. I've gone through these steps many times and I always find something new to try for the next time. Overall, I think it's best to use original, uncut axles if you can find the size you need, but sometimes you just need to go custom.

Discussion

Cheers, I think your last sentence "Overall, I think it's best to use original, uncut axles if you can find the size you need, but sometimes you just need to go custom." seems to make sense, but, if you use original uncut axles to reinstall, do you find best to "fix" in, or to leave some "suspension" type movement? Cheers, aka Marc D

I used to think fixing axles was the best most standard way, but some recent discussion about wheel irregularities has me wondering otherwise. Check out this post for more insight.

But in general I'd say fixing axles is fine because it should reduce the friction and so on. But there are a lot of factors that play into it, even then.

Hi All!

I'm pretty new to this hobby. So just putting it out there for some advice;

I see a lot of replacement Wheels/ Axle set on sale on E Bay Amazon etc. Are these suitable for Racing Die cast cars, or are they just for display? If for racing purposes, what would you recommend please?

Thanks.

- Most you find on Ebay will be for the purposes of display only, as they'll have rubber wheels. If you look specifically at "comolded" or "co-molded" or "Cold Molded" wheels, then you're looking at hard plastic, and those could potentially be good for racing. However, their cost isn't normally worth it, since you can take wheels off other cars much more cheaply. — GenX_VintageRacing

- Many thanks for the info Buddy. That’s cleared that up for Me just fine. I guess the best thing then is to pick up a few El Crappo cars that I don’t like (Yet!)and use them as doner cars . — Xavante

I have used small sewing pins with just the rounded metal heads on them and the tubing to make a new axle before. Don't know how this works in the racing world but I do more for dioramas and display. Hope this may help!

Hard Wire & Cable Cutters, use these to shear through axles and music wire versus, "slicing."

I'd like to provide this tip I learned from my RC Airplane building experience. In that hobby I used a lot of K&S Music Wire for landing gear and servo push rods. That material would put dents into the cutting edges of all my pliers. Then I discovered the HWAC (Harden Wire & Cable Cutter) and it changed my life.

Bonus tip: The shearing leaves a sharp edge that can easily hurt someone. Use a file to knock off the burr.

- Thank you. — Numbskull

- Which one are you using? — Numbskull

- Xuron branded, "Hard Wire & Cable Cutter." They seem pricey when I look them up now, but I've had mine for over two decades. If I had to buy them today knowing that, I'd still buy them in two heartbeats (not one, lol). — X2Whiskey

- I just replaced my xuron rail cutter (HO train track) after 3 layouts and well over 400 ft of track cut. (at least a decade) they are a quality tool, even at twice the price — dr_dodge

- 2193? — Numbskull

- Yes, 2193 is stamped on the side. Sorry for not thinking to provide that earlier. — X2Whiskey

- Well …. you need every ‘edge’ while racing. Does slicing up the wheels on your opponents’ cars count as ‘eliminating the competition’? — SpyDude

2193 is not the same as the 2193F

2193 -Hard Wire and Memory Wire Cutter

Designed for cutting memory wire and other types of hard wire. Also, a great tool for cutting push rods, throttle cable and carbon fiber rods and nichrome wire.

Cutting effort is minimal due to the tools' full bypass shearing action. Rated for cutting hard wire up to 0.040" diameter.

2193F -Hard Wire Cutter

Similar to our model 2193 but with self-adjusting clamping fixtures, which hold the wire perpedicular to the jaws. Greatly simplifies the cutting process while allowing for flat cuts on both the cut and cut-off sides of the wire.

Can be used to cut memory wire, silver, gold and copper wire. Also good for cutting twisted throttle cable. Cuts music wire up to 0.064" diameter.

The F version has a higher capacity cut. I use the F version... can't go wrong with either for our purposes.

hi redlinederby,

just want to confirm a few things.. by using a tube, doesn't it affect FTE's performance? since the only thing spinning are just the wheels.. CMIIW..

and 1 more .. can we fix a bent FTE axle? If yes, please share how.

thx for sharing..