The agony and ecstasy of seamless orange track

My first race track was simple and cheap - that was the point. Something I could put up and tear down with worry. Over a short amount of time, I had accumulated hundreds of feet of orange track segments of various types. My track box is a good look at the history of orange track. But then I learned about an orange track I didn’t know existed.

Hot Wheels seamless orange track.

The ecstasy

As Redline Derby grew and more people started sharing their stories, I learned that seamless orange track was a thing. And I wanted it.

The foot long track segments I had been using weren’t garbage, not by any stretch…plus, that’s what I had access to. I could get long straights at Toys R Us for a $1 a piece and it was glorious. But that’s not to say segmented track was perfect.

I often suffered the wrath of track walls at the joints. The corners of the walls would bend after a lot of in/out storage and racing. Having a car get snagged on the joint walls was not uncommon and it was frustrating. I wanted to race knowing my track was as fair as I could make it.

Once I knew that seamless track was an option, I was determined to get some. It’s not available in retail (or at least not anymore) and the only way to get it was secondhand, on eBay or wherever. My regular searches online found 50-foot rolls of seamless track selling for $75 and up. When you do the math, that’s not a bad deal, but that price usually went way up by the end of auctions and such.

I kept buying segments as I needed but Mattel started to change the orange track design, which meant I had to re-buy more so my track would be consistent. And then, after accumulating hundreds of feet of orange track segments, the toy gods smile upon me with some luck.

One of the RLD members had a roll of track and was looking to unload it. (After so many years, I’ve forgotten who it was - I’m sorry - if you’re still hanging around, chime in). He wanted $50 and that was a no-brainer. My wallet opened and days later a big, beautiful roll of seamless orange track was on my doorstep.

I was happy. I thought I had reached the upper levels track status. My track problems were all solved and I’d be worry free. Not quite.

The agony

While seamless track solves the joint problems, it comes with a whole host of other concerns…so many that I’ve often thought about returning to segmented track and just dealing with replacements and wall issues.

For one, as you would expect, getting a rolled up piece of plastic to unroll and stay flat is a chore. Armed with a hair dryer and some weights, I did battle for a few nights until I was happy with things. Thankfully, cutting the track is easy, and so I ended up with two, 18-feet lengths for the track and about 15-feet left over to play with.

Two middle lanes are full-lenth, near lane has the remainder.

I got my shelf track built and setup with my seamless track and figured the worst was behind me. But alas, there was one more battle to fight - waffling.

Long pieces of plastic are susceptible to changes in temperature. The plastic will expand and contract. This is true for segments too but is less noticeable since they can push/pull each other. And even though my track is in my basement where the environment is pretty consistent, plastic is plastic, and that means it can wrinkle up in spots, or “waffle.”

Waffling can make cars bounce more than it should, like going over tiny speed bumps. The track then also has a hard time laying flat on your track base, which means you have to introduce add-ons to help, whether that be Velcro, magnets, screws, or some other technique.

Another issue I’ve found with seamless is that the track will bow across the the track, convex style. I’m sure it’s because the single piece of plastic is so long but regardless of the science, it’s annoying. If the track is too bowed, it’s hard for the cars to not ride against the walls. Shorter, segmented track doesn’t seem to have this issue, or if it does, it’s only for a few segments and not the entire length of the track.

I tried different solutions over time but I finally landed on using some aluminum strips I found at Home Depot that fit into the track connector channel perfectly. This has helped the waffling and also adds a little weight that keeps the track sitting on the base board. I’m not sure it has helped solve the minimal bowing but I took my wins where I could get them.

However, the greatest trap of seamless track is the obvious one - it’s not readily available, anywhere! This was a calculated risk that I took, thinking the benefits of two lanes of seamless would be light at the end of the tunnel. But what to do when I want 4 lanes of racing? Or even if I want another layout, or add a jump or something? I’m not gonna mix-n-match track types. Going seamless locks you into one-off custom track land (just like any custom thing) and that can be expensive (or even impossible) to maintain later down the road.

Yet after all this, I’ve accepted my track as what it is. I’m happy with it and just have to remind myself that we’re racing toy cars for fun. This ain’t hard science and we’re not F1 or the Olympics here. A few little hiccups just means I’m human.

Judgement

Is having seamless orange track nice? Yes. Does it make you feel cool and special? Yes. Does it look cool in photos? Totally.

Is seamless track worth it? Maybe but probably not.

After investing heavily in segmented track at the start, I probably just should have kept going down that road and not bothered with seamless at all. It’s probably better to stick with what’s readily available at retail. You’ll never have to worry about running out of stock and you won’t be locked into one track layout or style.

And every time I get my track prepped for racing, I always find myself asking, “was dealing with the track joints really that bad?”

Discussion

BluTrack is a smidge wider but in my experience it does not lay flat well at all. I think since it's once wide piece the tendency to twist/warp is even greater...?

When you routed channels on your base board, did the orange track slide on those nicely and stay? I'd think if you had the 1/16 channels that fit the track as-is, you wouldn't even need glue.

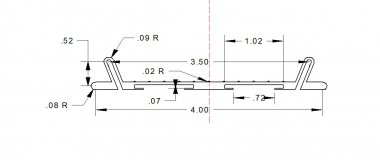

And check out these aluminum strips I found at Home Depot...they slide in the track channels really well. Doesn't solve the problems entirely but doesn't hurt. Helps quite a bit I've found.

Thanks for this.I have woundered over the years if the 50 ft rolls were a better Track system.This explanes both the good and the bad.I have several feet of the old style track.It's not perfect either,but fun to say the least..

Rusty H

I've had my seamless track setup for 5 years about and I'm very happy with it, despite the challenges the track can bring. I went in expecting to be racing more often for the fantasy league stuff so I didn't mind being limited to a straight up drag strip. I wasn't interested in jumps or alternate setup.

The only real bummer I have right now is that I only have 2 lanes that are seamless. I'd need another 50' roll to give me 4 lanes of consistent racing. If I wanted to do a 4-lane race, I'd have to swap out the seamless for segmented across all lanes.

Since you posted this I've been thinking of ways to fix this issue. So I went to lowes to look around and this is what I'm gonna try.

Its a flat automotive fastener for GM vehicles. It fits perfectly between the "rails". I tested a short section of orange track and it sits perectly flat...so im gonna drill holes every foot or so install these in the track then push them into the holes. Then you can trim the excess from the underside of the base board. The package comes with two, and lowes only had one package, so I ordered more and will install and test when they get here. I'll let yall know how it turns out.

I tried something similar just with regular metal washers but didn't like it much. It ended up making little bumps in the track that were 1" wide. What you found looks like it will work great, especially with that long shaft. Keep us up to date with what you find out.

What 3DBM needs to make with his fancy 3D printer is a long connector that works the same way. Make it so you can pinch the shaft together and put the flat "head" under the track so you don't have to slide it all the way down the seamless track. Then release and it goes into the channels. I think it could be several inches long too.

I think I just came up with a great excuse to buy my own 3D printer, ha!

- Yes, I also tried washers and screws, but it was with the short sections and blue connectors. With the fasteners the idea is I wont have to slide the track down the washers...since its one continuous piece. Instead i can install the fasteners and slide them to the predrilled holes and press them in hopefully tighter than screws and washers. We'll see. Go Cowboys! — Go_Time

Just wanted to post an update on my experiment...Well, it worked out GREAT! the track sits flat, and there are no bumps with the fasteners. I drilled holes every 6" but placed the fasteners every foot, the plan was to see if there were any spots that needed additional fasteners and "fill them in" as needed. But it turns out the one foot spacing worked great, I might add one more fastener closer to the start. Is this the BEST way to fasten a seamless track, I don't know, but it is working better than anything I had previously tried. I've been trying to think of a negative to this method and I will say its gonna be a bit of a pain to disassemble the track as the fasteners do sit pretty tight in the drilled holes.

- Looks great...quality work — LeagueofSpeed

- Awesome idea and looks like it's doing the job very nicely — Chaos_Canyon

That was me! I had found and bought a 2 for 1 deal and kept one and contacted you reading here that you were interested and sold/shipped one to you. I see your points-issues but I haven’t moved it more than a couple times in 5 years. I used Velcro and it’s been flat....until now! I’ve now added a turn at the end.. which twists up the seamless track and if a car takes the turn too fast it will often fall off. Too slow and it won’t make the turn.. I’ve used duct tape! Haha

I think the best part of this thread is the beginning. I have read it over and over, since I came on here. I have always envied one piece track, it looks so cool and it seems like all your problems are gone. What I really like is the solutions here and the fact that I have never read, " toss the crap out." So.. last week I came across 2 NIB 50 foot track like pictured above. There is NO WAY one can resist when its right in front of you. Even if I had read here.. its crap stay away, I foolishly would have bought it. I have yet to open either, I need a plan , then an action plan before I crack even one open. I haven't decided. Total impulse buy and at what would be about $35 USD for each one, I think I am ok pricewise. I am hovering between 4 25 foot lanes or find a location for 2 50 foot lanes. Looks like a good number of solutions to choose when it comes time to fasten it down.

- If you got a roll for $35, you got a steal! Bravo — redlinederby

- two of them $35 each $70 , S100 cdn for the two boxes, 100 feet of track — madmax

- Wow, what a great price! I have had a four lane sectional orange track set up for some months now. And yes, the maintenance issues have been frustrating! However trying to find and get 50ft HW seamless.. Wow, must be gold plated, on Amazon $144 US. Blutrack would be a more economical option, but no so if the track is no good? Idk? — CutRock_R_Marc_D

In the rebuilding of my home track, I've found that when you have a full 4 lanes and are using currently available starting gates (and some finish lines), the track gets squished together in a most undesirable way. The reason is that the gates people are making are made for the currently available orange - which makes complete sense.

However, the seamless orange track has higher walls which means the lanes need to be further apart so as to not squeese against each other. Bummer. This isn't something I had to worry until now because I didn't have a full 4 lanes, I just had 2.

Sadly, there's not easy solution for this that I can see. I wouldn't expect makers to design a gate or finish to fit track that only a few people have. I'm going to have to go back to the drawing board to come up with a mechanism that will happily manage my seamless orange.

So once again, this seamless stuff is almost more trouble than it's worth...but I'm in too deep now to give up on it.

- D64e the rookie that robby does I think in an episode he posted how to build a gate like his. Which is the flip up style. — NDeavers80

- https://youtu.be/Df-O_nRZ7pI — NDeavers80

- https://youtu.be/OpvKwwf1LGw — NDeavers80

Do these problems apply to Blutrack as well? This seems like the same idea as Blutrack.

- In my opinion, Blutrack is worse. I'm not sure if it's because it's a different plastic or just wider or what but keeping Blutrack straight is an exercise in futility. But if you're going to nail it down or whatever, then probably less so. — redlinederby

I have dealt with the exact same issues as you, I completely ruined an orange seamless track trying to glue it to the base...DO NOT TRY GLUE...TRUST ME, LOL. I routed channels that the "rails" underneath would fit in and the plan was to use glue to secure it, COMPLETE FAIL. I'm on my second seamless track and am currently using velcro...its ok, I also have a third seamless track on the shelf for when someone comes up with the best no fail idea. I have considered purchasing blue track as it seems to sit flat with no "rails" underneath. Also, I believe the blue track is a hair wider, which I think would be perfect for testing/racing, as it would force you to build cars that track as straight as possible.